Contact mechanics and seal leakage

Seals are devices to close a gap and to prevent fluid flow through a joint. Although seals play a crucial role in many modern engineering devices, inexpensive elastomeric seals such as O-rings are often used. The failure of seals can have serious ramifications ranging from energy loss, environmental pollution, expensive and time-consuming replacement procedures all the way to catastrophic events like the Challenger disaster. Thus, seal systems should be handled as thoroughly in the design process as any other crucial machine element, and not like a secondary accessory.

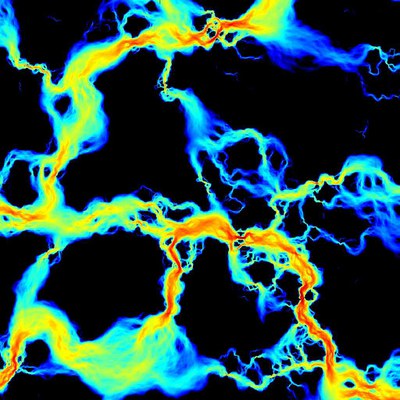

In our simulations, we study fluid flow at the interfaces between elastic solids with randomly rough, self-affine surfaces. A trademark of our work is that we do not invoke any uncontrolled approximations. Contact mechanics are solved with Green’s function molecular dynamics. The interfacial separation that we obtain in these calculations is then used as boundary condition for the solution of Reynolds thin film equation. The simulations allow us to test strengths and weaknesses of theories and to improve the theories to come up with better predictions for leak rates.

In the figure, you can see a small fraction of the interface between a seal and a substrate. Brighter colors indicate increased flow.

Reference:

W. Dapp and M. Müser, Fluid leakage near the percolation threshold,

Scientific reports 6, 19513 (2016)

DOI: 10.1038/srep19513